Properties of Tungsten Carbides

Most affect to the properties of Tungsten Carbide have the amount of Cobalt (binder) used and the grain size of the Wolfram Carbide powder. Wear resistance of Tungsten Carbide parts can be over 50-fold, in the best solutions even 100-fold, compared to the best tool steels. Compressive strength, rigidity and thermal conductivity are superior.

As a material Tungsten Carbide is superior material in many solutions. Tungsten Carbide products are also price competitive compared to the tool steels despite that the wear resistance of Tungsten Carbide products is much higher. The best features of Tungsten Carbide are wear resistance, compressive strength, elasticity, rigidity (applications such as long boring tools), high temperature tolerance (at 1000 °C over 80 % of the tensile properties still remain), good thermal conductivity, easy to polish, excellent resistance to thermal shocks and very easy to coat (with TiN, TiC, MoC and diamond coatings).

We can supply a material specification of our Tungsten Carbide products when needed.

As a material Tungsten Carbide is superior material in many solutions. Tungsten Carbide products are also price competitive compared to the tool steels despite that the wear resistance of Tungsten Carbide products is much higher. The best features of Tungsten Carbide are wear resistance, compressive strength, elasticity, rigidity (applications such as long boring tools), high temperature tolerance (at 1000 °C over 80 % of the tensile properties still remain), good thermal conductivity, easy to polish, excellent resistance to thermal shocks and very easy to coat (with TiN, TiC, MoC and diamond coatings).

We can supply a material specification of our Tungsten Carbide products when needed.

Some Tungsten Carbide Grades

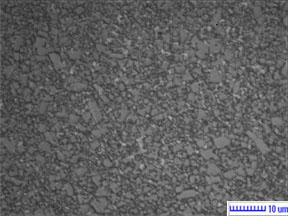

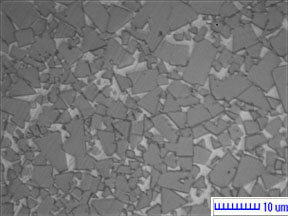

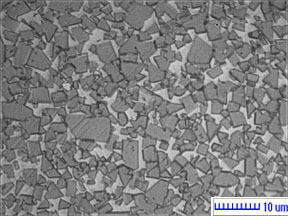

Tungsten Carbide structure enlarged to 1.500 X. Dark granules are hard Wolfram Carbides, light areas are Cobalt as binder.